|

||

|

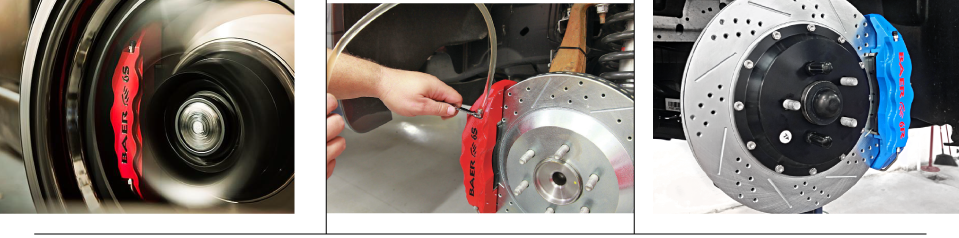

Below you will find our Technical Information, including Instructions and How-to’s Videos. Instructions are issued by Baer Brakes to ensure a safe and proper installation. Please read the Instructions carefully and make sure that all required tools are available prior to beginning the installation. Online viewing and downloading of Instructions are FREE. Adobe Reader is required to view the instructions. |

|

|

||

|

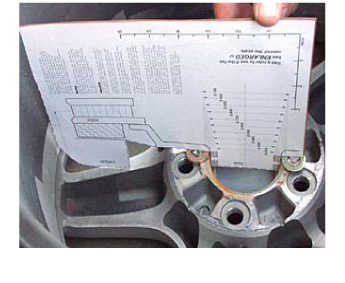

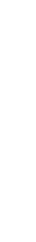

Because of the abundance of wheel companies and styles, it is impossible for Baer to guarantee fit of their brake systems into a specific wheel style and/or manufacturer. To verify fitment of a specific Baer brake upgrade, we recommend using our brake system template. The templates are listed with the part number of the brake system in our application charts. Download the instructions HERE |

|

|

|

||||||||||

|

One step in preparing the brake system for duty is to "Season" the rotors, relieving the internal stresses within the material. Another step is to "Bed" the brake pads. Download the instructions HERE |

|

Always remember, good-to-excellent brakes or fluid do not function without adequate cooling. In fact, the more serious your brake system, the more attention needs to be directed to proper ducting, as they will generate more heat due to the increased capacity. Download the instructions for the bleeding procedure HERE |

|

The EradiSpeed+ and EradiSpeed+1 are a 2-piece design, with an aluminum center hat bolted to the rotor ring, which will eventually need to be replaced. Download the instructions for installing a new rotor onto the aluminum hat HERE |

|

||||

|

||||||||||

|

|

|||||||||

|

||||||||||

|

|||

|

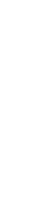

Rotors that are directionally ventilated must rotate in the correct direction to obtain proper airflow for cooling. Download the instructions HERE |

|

|

|

|||

|

Baer Inc. has expanding its line of performance brake products with the introduction of the Remaster: a fully machined billet aluminum master cylinder unlike any other available today. Baer engineered the Remaster with a compact design to make fitments easier in a variety of applications. Download the instructions instructions HERE Download the tech sheets HERE |

|

|

|

|||

|

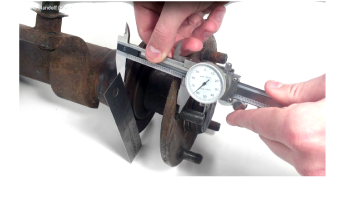

This video is about axle standoff, otherwise known as brake space. The instructional video we will teach you what axle standoff is, and how to measure it. Understanding axle standoff, and knowing how to measure it is very important because it determines how the caliper will line up over the brake rotor. |

|

|

|

||||||

|

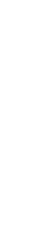

Ford, Chevrolet, Oldsmobile, Pontiac and Dodge all used a different axle flange at one point or another. Being able to identify your flange type can save you a lot of worry and speed up the whole process. The graphic here is to help you identify yours. Click HERE to se all flange types. |

|

||||

|

|||

|

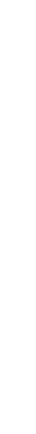

Occasionally installing after-market brake system require modification of the stock spindle. These mods can include having to cut, grind, drill, and tap the spindle in order to make it compliant with the after-market system, and most brake manufacturers leave this harrowing task to the customer. At Baer, when you order a system that requires spindle modification we actually make the modifications in house with a CNC machine and include the modified spindle in your order. Saving the customer from having to do this themselves in only one of the advantages, by cutting with a CNC machine we ensure precise conversions are made eliminating the risk of misalignment occurring. |

|

|

|

|||

|

|||

|

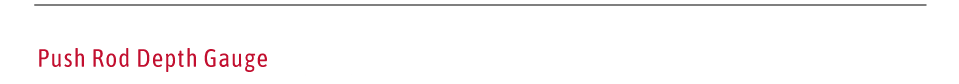

This is a very simple tool but one that should be in every mechanic’s tool box. The tool is used for measuring and determining the difference between the booster pin and the master cylinder piston. Baer recommends at least .005” clearance. Download the instructions HERE |

|

|

|

|||

|

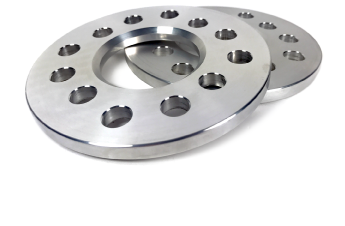

The Baer wheel spacer is a great tool to get a desired brake system to fit inside a wheel. They are fully machined in house from US sourced 6061-T6 aluminum to ensure they are flat and true to form and are available in a wide variety of bolt patterns and sizes to ensure the perfect fitment for your application! Download the tech sheet HERE |

|

|